While facilitating an improvement project for a hospital’s surgical department recently, our team was presented with a clear opportunity for improvement. Recent data logged during a long day of procedures included three separate surgical cases where the patient’s discharge paperwork was incorrect. These three errors were all caught by the surgeon before the patient was discharged. Unfortunately, however, other patients had reported receiving and following the wrong post-op procedures.

The team decided that this issue was a priority to address. The Nursing Director took a leadership role in bringing together the team involved in preparing the pre-op paperwork. They reviewed the problem and proposed solutions. The team was able to work together to quickly make some significant improvements while learning some core concepts of problem-solving. Some of the tools and techniques that the team followed are summarized below.

-

Identify the cause(s) of the problem

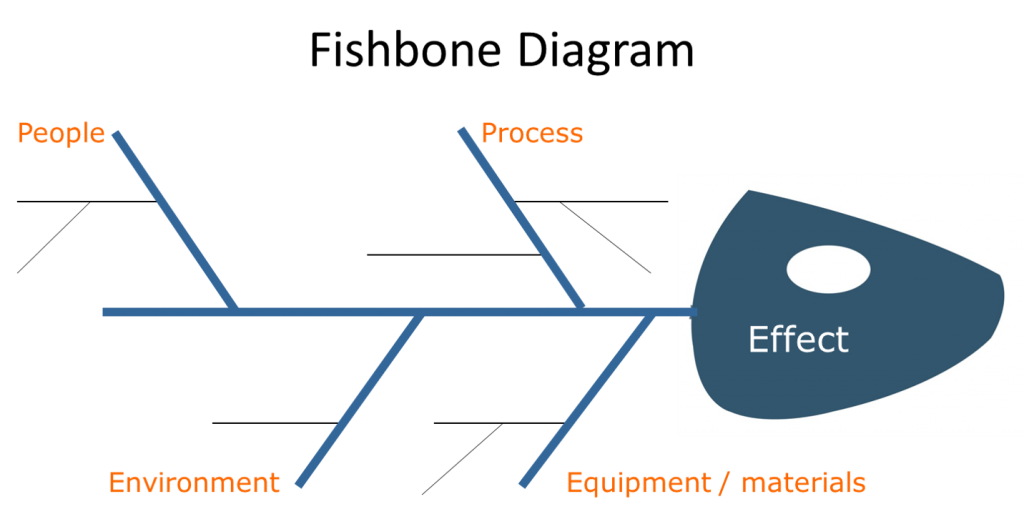

Problems are just the negative effects that are caused by failures of a process or system. One great tool for identifying the causes of a problem is a fishbone diagram. This is also sometimes called an Ishikawa or cause-effect diagram. By starting with the problem, or effect, you work backward to identify possible causes.

Let’s use the problem of “wrong discharge instructions were given to the patient.” Our healthcare team informally identified several possible causes including:

- The wrong discharge instructions are being pulled from the file.

- Misfiling of the discharge instructions.

- The surgeon’s orders are being misread or misinterpreted.

- An error was made in the patient booking process.

- The procedure was changed after the discharge orders were set up.

-

Go to the Gemba

When identifying the causes of a problem don’t do it alone and definitely don’t do it in a meeting room. Remember the concept of the 3 Reals:

“Go to the real place to observe the real thing to get the real facts and data.”

The Japanese word “gemba” translates to “the real place” and is often used as a reminder of the value of observing the actual process or system. Managers should make “gemba walks” a regular part of their day. The most successful problem solvers not only address the problem in the real place, but they also address it right after it occurs. They also address it before the situation has changed. It is often easier for an outsider who does not deal with the process every day to identify the causes of the problem.

Our improvement team was able to see one possible cause of discharge instructions being pulled from the wrong file only when we went to gemba. Looking at the actual discharge instruction files it was easy to see that a file folder was mislabeled. The correction was completed in about a minute.

-

Get to the root cause(s) of the problem

When dealing with the dandelions and other weeds that grow in my yard I have learned that cutting off the flower or pulling off the leaves is just a short-term fix. My lawn may look good for a few weeks, but it is inevitable that those weeds will grow back and I will need to deal with them again. Most of our problems and issues are just like those weeds; if we want to prevent them from coming back we need to dig deep and get to the root. Correctly identifying the root cause is the key to effective problem solving.

Toyota popularized the method of asking “why?” at least five times. This can be done informally or formally in a cause-and-effect diagram. For some problems, you may get to root cause in only a few “whys?” However, for complex issues, you may need to ask more than five. Keep in mind that 99% of the time the process or system is at fault, not a person. People do not fail, processes do.

Members of our healthcare improvement team were able to see that the complexity of the ordering instruction system was a root cause of many of the issues. Once they arrived at this root cause it was possible to look at solutions that would combine and consolidate the paperwork. Part of the solution involved changing the process to one with only a few variables: inpatient or outpatient, diabetic patient or not diabetic, etc. Simplifying the process was also an opportunity for the staff to implement some mistake-proofing.

People do not fail, processes do.

Hopefully, these three tips can benefit your team as you tackle challenging problems. Please let us know of a time when you successfully completed problem solving to root cause.