Organize the Workplace, Effectively

The Principle:

Less waste = More value

The 5S methodology aids us in reducing waste in the workplace.

Waste is anything other than the MINIMUM of equipment, supplies, space and a worker’s time that add value to the product or service

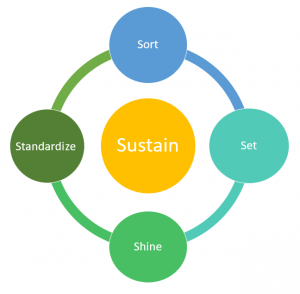

SORT

•Organize

•Eliminate waste

STRAIGHTEN

• Everything has a place

• Keep everything in place

SHINE

• Cleanliness

• Keep clean and tidy

STANDARDIZE

• Adherence

• Maintain the first 3 pillars

SUSTAIN

• Discipline

• Procedures become habits

5S is a Toyota-born concept:

At Toyota, an emphasis on reducing any waste is paramount. Visual controls are integrated into processes to assist workers to maintain an ideal working state. The visual aspect means being able to look at a process, a piece of equipment, inventory, information, or at a worker performing a job and immediately see if the standard for performing the task is being used or if there is a deviation from the standard.

We can think of common visual controls that all of us use a in our everyday lives. For example, consider traffic signs. Good traffic signs do not require you to study them- you see them and the meaning is immediately clear.

We teach 5S and other Lean Tools in our Intro to Lean Thinking courses.