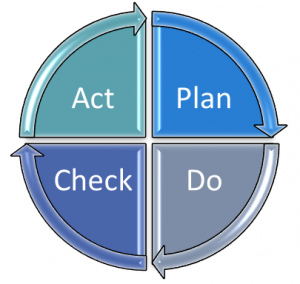

PDCA

The simple Plan, Do, Check, Adjust (PDCA) methodology is used by lean organizations that promote a culture of continuous improvement. PDCA is used for conducting small improvement “experiments” and measuring how they influence key outcomes.

The simple Plan, Do, Check, Adjust (PDCA) methodology is used by lean organizations that promote a culture of continuous improvement. PDCA is used for conducting small improvement “experiments” and measuring how they influence key outcomes.

PLAN: First, understand the problem (actual condition) and the desired outcome (target condition).

DO: Then, implement a change

CHECK: Study the results of your experiment. What did you try? What did you expect as an outcome? What actually happened? What did you learn during your trial?

ADJUST: Adjust the standard process based upon what you have learned. Should you adopt your change as a standard part of the process? Or should you adjust the action and measure results again?

See our blog posts “Ready… Fire!… Aim” and “The Power of A3 Process Improvement” for examples of PDCA in action.

Our ‘Introduction to Lean Thinking‘ Course will introduce your team to this and other powerful Lean tools and concepts.