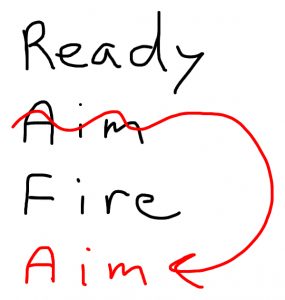

In the 21st century, it is necessary for continuous improvement to become a habit ingrained within organizations. Change today occurs so quickly – you either improve or fall behind your peers. Lean East teaches you to get Ready . . . Fire! . . . and then Aim using PDCA continuous improvement.

How can organizations and teams establish continuous improvement practices and habits?

Michael Masterson’s book Ready, Fire, Aim: Zero to $100 Million in No Time Flat teaches us that a key step in continuous improvement is usually the first one – taking action. Begin by realizing that no change effort is ever going to achieve perfection. Over-planning a change loses momentum and interest from the team; another problem will soon develop that pushes the current issue aside. Perfection can be the enemy of “good enough.”

“You don’t have to be great to start, but you have to start to be great.” ~ Zig Ziglar

Ready…Fire!…Aim

In many organizations, people and teams are debilitated by a fear of failure. When risk aversion is part of the culture and risk-taking is not rewarded, developing a bias to action is never easy. Encouraging a team to test a change – take a shot and Fire!, even if the test fails – must be a goal when establishing a culture of continuous improvement.

Most complex problems are multi-faceted and do not have obvious solutions. Any time you and your team aren’t sure how to start planning a solution, your best bet may be to limit the problem-solving discussion to 5 minutes and then . . . try something!

![]()

Here is the simple Lean East model, based upon Plan-Do-Check-Adjust (PDCA) methods:

PDCA Continuous Improvement

PREPARE (Plan)

- Identify an outcome you want – your goal or target condition.

- You are measuring this goal . . . right? If you aren’t already measuring your outcome then is it really important to your customer? If so, you must set up a simple way to measure the outcome. How would your customer measure it?

- If you don’t have a consistent process or standardized way of achieving your outcome . . . STOP! Your immediate need is to standardize the process. Get the team together and decide upon one way to achieve the process from now on . . . and measure the results.

- Once you have a standard process and a way to measure your goal,

- Reflect on the actual condition right now – what obstacles can you identify that are preventing you from meeting your goal? Discuss them, brainstorm them as a team, ask your customer, etc.

READY (Plan)

- Pick one obstacle and identify one action you can take right now that you believe will eliminate that one obstacle. (Yes, this means keeping everything else the same so work on this as a team. A morning huddle is a great time to review this.)

- What do you expect will happen because of your change?

- How quickly can you measure and evaluate the results of this one change?

FIRE! (Do)

- Take the action! Now, not later. You are seeking feedback. Even a failure to improve the outcome will be a learning and growth experience.

AIM (Check)

- Reflect on the action as soon as you have some measures of the result. Hopefully, this is by the end of the shift or by the next morning. You should review outcomes at least on a daily basis, even if the decision is to collect more data.

- What did you try?

- What did you expect as an outcome?

- What actually happened?

- What did you learn during your trial?

Adjust

- You will use this new knowledge to adjust your aim before you try something else. The goal is to have quick feedback so you can re-aim at your target the next day. This final step of one iteration of the PDCA process calls you to ask: should you adopt your change as a standard part of the process? Or should you adjust the action and measure the results again?

- Ask yourself – Have you met your goal? Have you identified other obstacles to achieving your goal? On to the next Iteration. Return to step 3 and repeat!

Continuous Improvement = Learning

Remember that we all have many arrows in our quiver; it is better to take action and learn from our trial rather than delay getting started.

Don’t be afraid of trying and failing – that is part of learning.

Imagine a team that takes a week to decide to work on a project, or to obtain management permission to start an improvement project. What if instead, the team tried out five different solutions to learn what works and what doesn’t work? Each “miss” provides valuable feedback, not to mention practice. Develop new habits that avoid “paralysis by analysis” and then try something!

Lean East works with leaders to ensure they are not only endorsing continuous improvement efforts but reinforcing habits of success. Individuals and teams must be coached to improve on a daily basis. Practicing problem-solving and critical thinking skills regularly will form new neural pathways and eventually develop good habits. Over time these habits will change the mindset of the organization. Over many years this mindset leads to a continuous improvement culture.

Please contact us if you’d like to learn how we can help your team implement a culture of continuous improvement, and share this summary with others if you find these ideas for action helpful.

Related Posts

Is Your Organization High-Performing? Take Our FREE Performance Assessment

The God Complex: Why We’re All Making This One Mistake

How I am Changing the Career Advice I Give My Kids