How SMED – Single Minute Exchange of Dies – Reduces Changeovers

Lean East shares how SMED – Single Minute Exchange of Dies – can help you reduce your changeover times so you are more efficient and productive

Lean East shares how SMED – Single Minute Exchange of Dies – can help you reduce your changeover times so you are more efficient and productive

Lean East shares the relationship between the Lean Japanese terms muda, mura, and muri. Learn to eliminate waste, unevenness, and overburden!

Lean East shares the difference between a focus on problems or solutions in a current state analysis

The Lean East team shares how to use the 5 Whys for Root Cause Analysis in Lean and provides a few examples.

The Lean East team shares a few techniques and advantages of Poka-Yoke, the Japanese term for mistake proofing.

The Lean East team shares a crash course on the many organizational improvement methodologies and when to apply them.

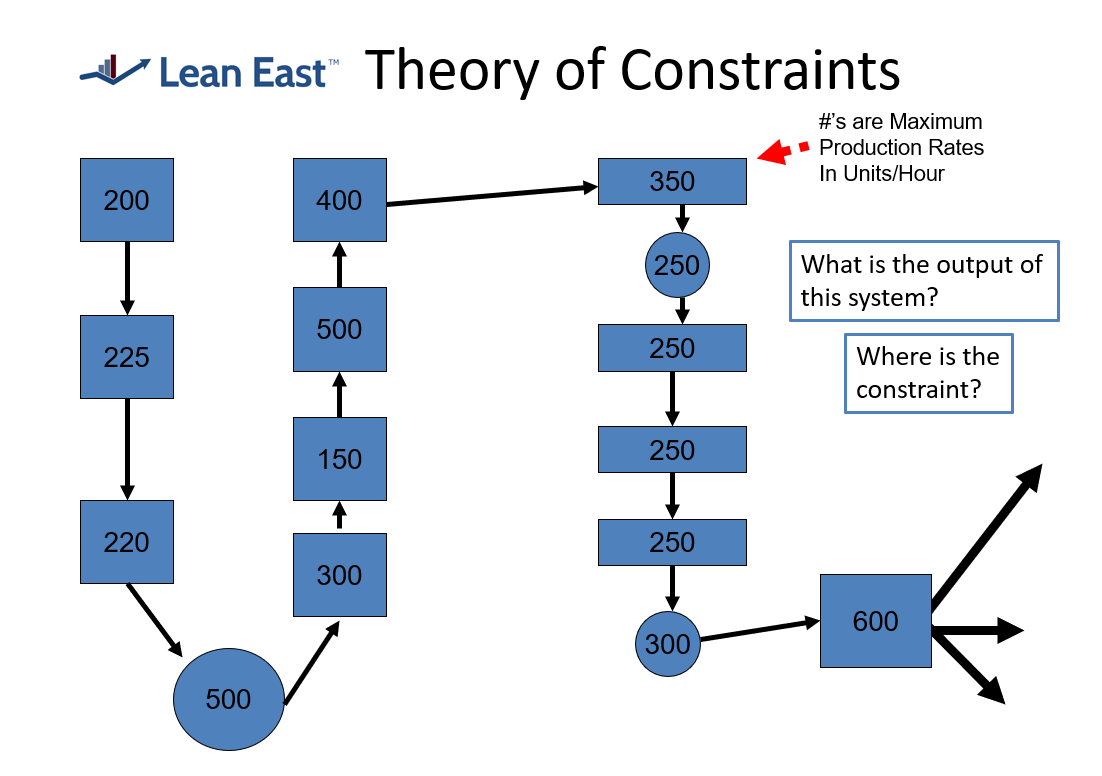

“The Goal: A Process of Ongoing Improvement” by Eli Goldratt. Learn how to use the Theory of Constraints to identify and eliminate process bottlenecks.

Lean East clients experience increased profit and improved outcomes. Our business case for Lean thinking and Lean engagements includes five client examples.

We define and explain the differences between push and pull in Lean Six Sigma, and why the goal is to “flow value at the pull of the customer.”

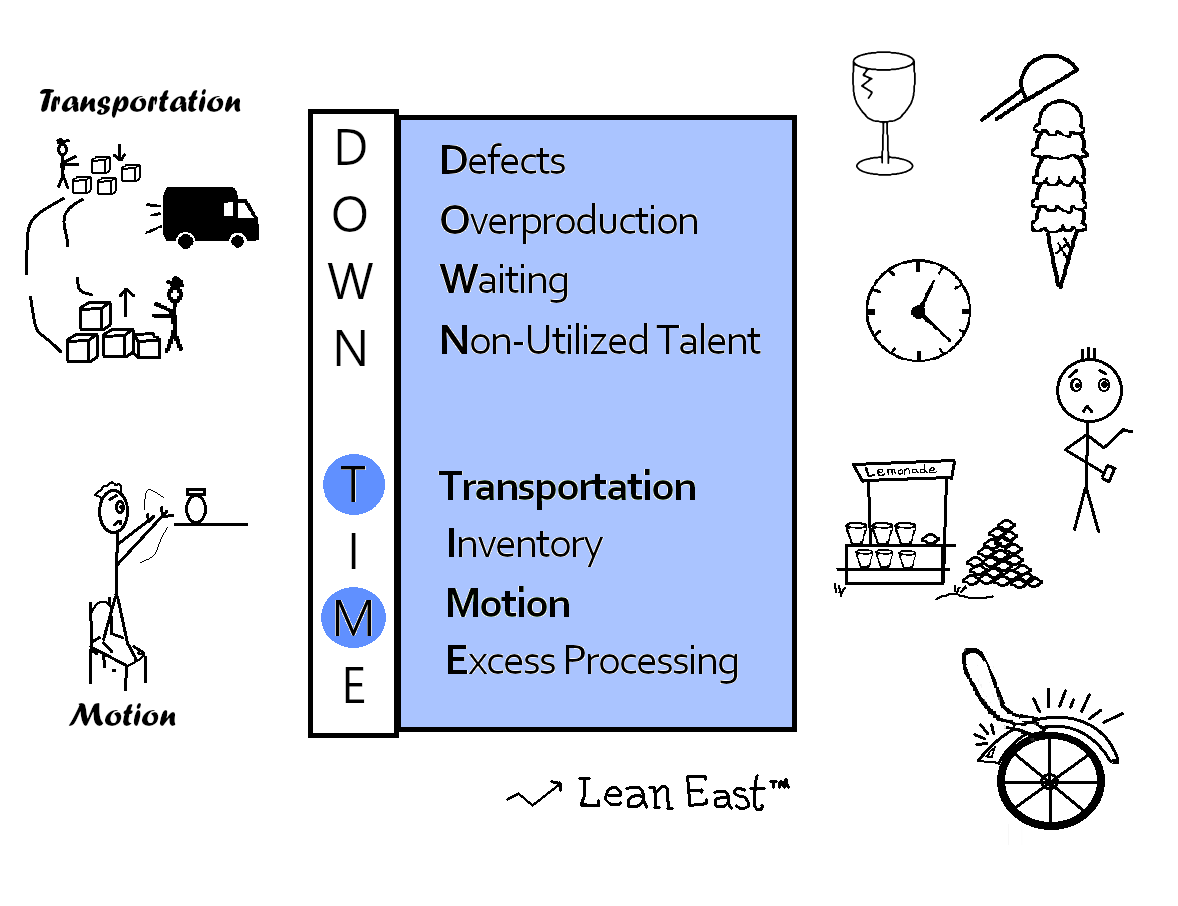

Learn the difference between the Lean wastes of Motion and Transportation (with examples) and how to eliminate these wastes from your processes.

Our website uses cookies to improve and personalize your experience. Our website may also include cookies from third parties like Google Analytics. By using the website, you consent to the use of cookies. Please check our Privacy Policy at the bottom of the page.