The Lean East team recently completed another session of our popular Lean Six Sigma Green Belt training for a client. The 6-day course teaches process improvement tools and methods for removing wastes, minimizing variation, and managing constraints in a system. We focus on Lean Six Sigma principles but also include exposure to principles from the Theory of Constraints (TOC), Operational Excellence (OpEx), and project facilitation skills. This post is a summary of many organizational improvement methodologies (from past to present) and when to apply them.

Lean

Lean principles are based on Toyota’s principles of continuous improvement. Our clients at Lean East should already be aware of the principles as they have been covered many times in this blog, including our page on What is Lean, Kata, Personal Kaizen, etc.

Lean focuses primarily on identifying the customer value in processes and eliminating the work that does not create value – also known as waste. Continuous flow of value at the pull of the customer is the goal.

Lean East finds Lean principles form an important basis for any organization. We especially agree with the principles in the Toyota Way of “Respect for People” and “Continuous Improvement.”

Six Sigma

Six Sigma combines well with and overlaps Lean thinking. It also uses statistical methods to optimize processes and reduce process variation. A process that is operating at a “Six Sigma” level is in control and has less than three failures per million.

We share the basic principles and methods of Six Sigma here.

Theory of Constraints

The theory of constraints (TOC) is a simple philosophy popularized by Eli Goldratt in his 1984 book, The Goal: A Process of Ongoing Improvement. TOC focuses on identifying process constraints (bottlenecks and weak links). All systems are limited by their bottleneck and TOC methods help identify the bottleneck, subordinate the rest of your system to the bottleneck, and then elevate the bottleneck to improve the system output.

The link above shares more about the theory of TOC and its application. The Theory of Constraints overlaps with Lean thinking but from a different viewpoint.

Agile

Agile began with a manifesto written by software developers frustrated with traditional project management methods. The simple methods are based on Lean innovation theory (even referencing Lean concepts like kanban) and have become the predominant way software is developed and improved today.

To learn more, we have previously compared and contrasted Lean and Agile in this post.

Operational Excellence (OpEx)

Operational Excellence is a name many organizations use for their quality improvement efforts. It is an idea first introduced in the 1970s by Dr. Joseph Juran when working with Toyota. OpEx (not to be confused with the business finance acronym for Operational Expense) means every employee can see, deliver, and improve the flow of value to a customer. If you think that sounds like Lean thinking, you are correct!

Juran’s original model for operational excellence includes:

1. Develop an integrated management system to operate the organization.

2. Develop a culture of doing the right thing, the right way, every time.

3. Understand when and how to engage leadership and the workforce to drive performance.

4. Build an effective and efficient change infrastructure.

5. Drive business process effectiveness and agility.

The Lean East PERFORMANCE™ Process

The Lean East PERFROMANCE™ Process is our proven method for developing an integrated management system that supports Lean thinking and principles of respect for people and continuous improvement.

Learn more about the benefits of the Lean East PERFROMANCE™ Process here.

Hoshin Kanri

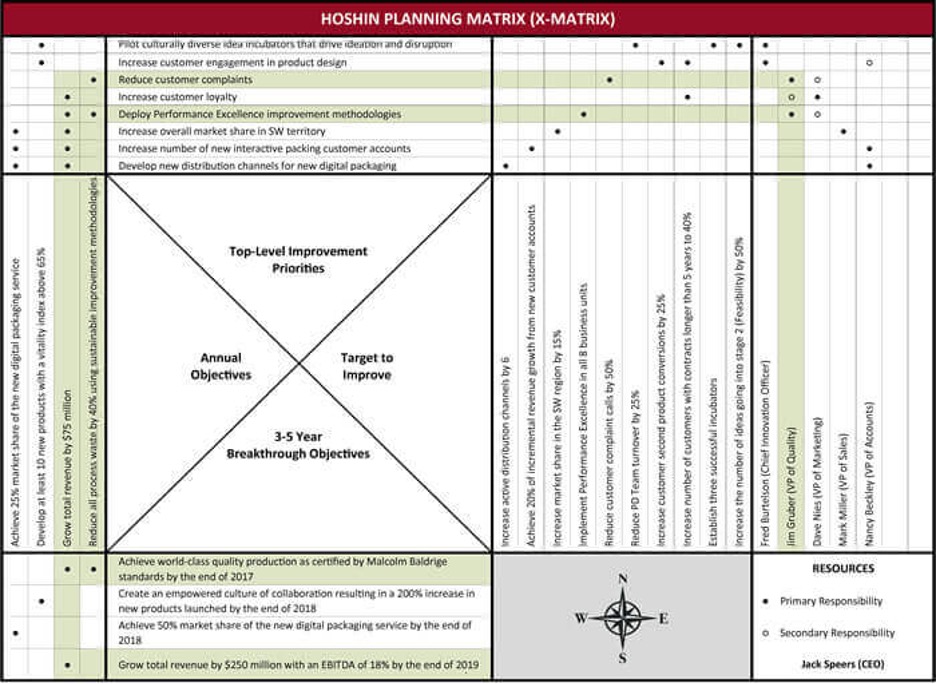

Hoshini Kanri is the Japanese phrase for “compass management.” It is a method used by Lean organizations for understanding your “true north” vision and creating and communicating a strategic plan for the organization.

The X-matrix is the tool many may be familiar with. Hoshin-Kanri concepts are included in the Lean East PERFROMANCE™ Process described above, but we have found the X-matrix to be overly complex for most organizations.

Toyota Production System (TPS)

The Toyota Production System (TPS) comprises the management philosophy and practices of Toyota and is a precursor to Lean thinking. For most people, it is synonymous with Lean thinking.

TPS has two main conceptual pillars:

- Just-in-time: “Making only what is needed, only when it is needed, and only in the amount that is needed”

- Jidoka: “Automation with a human touch”

The Toyota Way summarizes key principles of TPS.

PMP: Project Management

One popular certification is the Project Management Professional (PMP)® designation awarded by the Project Management Institute. To obtain PMP certification, a project manager must attend training on the Project Management Body of Knowledge (PMBOK), pass a 180-question exam, and meet certain other requirements. There are over one million PMPs as of 2023.

A PMP learns tools and techniques for managing projects in larger organizations. The PMBOK focuses on traditional (waterfall) projects that break out the work into smaller parts rather than Agile methodology.

Lean East touches upon aspects of the PMBOK methods of management and facilitation in our Lean Six Sigma Green Belt course.

Total Quality Management (TQM) and Total Productive Maintenance (TPM)

These two related approaches became popular in the 1980s and 1990s due to competition from Japan’s ability to produce high-quality goods at a competitive cost. If you speak with a manufacturer who is 55+ years old they will likely know one or both of these terms.

TQM and TPM both have significant overlap with Lean Manufacturing methods. Today these organizational improvement methodologies are included within Lean thinking.

Which of These Methods Should I Apply and When?

Now that we have covered popular organizational improvement and management methods, when should you use each theory?

First, we will note that Lean and Six Sigma are typically combined into a single methodology today. The Theory of Constraints, OpEx, TPS, TQM, and TPM all now fit without the concepts of Lean Six Sigma.

The remaining concepts are shown in the chart below, with our recommendation for where the organizational improvement methodologies are relevant.

| Method | Strategic Planning (Who, What, Why) | Operating Principles (Day-to-Day) | Execution (Projects & Change) |

| Lean Six Sigma | Lean Principles | PDCA – Tests of Change | |

| Hoshin Kanri | Communicates Strategic Plan | ||

| PERFORMANCE Process | Planning and Operating System | ||

| Agile | Iterative/Feedback | ||

| PMP | Waterfall (Linear) |

We use the Lean East PERFROMANCE™ Process for Strategic Planning and to help leaders respond to issues and measure results. Hoshin Kanri is a related method that is more complex. Both complement Lean Six Sigma principles.

Lean Six Sigma principles of increasing customer value, reducing waste and variation, and continuous improvement are the gold standard today. Manufacturers figured this out years ago, Lean East is helping service-based companies implement Lean.

Agile and traditional Project Management principles help with the execution of change. Lean East teaches the simple PDCA methods for improvement and then methods from Agile or PMP principles for larger projects.

Summary

We hope this overview helped you understand the differences (and similarities) between these organizational improvement methodologies. Please reach out to the Lean East team for training and support at your organization.

Related Posts

Is Your Organization High-Performing? Take Our FREE Performance Assessment

The God Complex: Why We’re All Making This One Mistake

How I am Changing the Career Advice I Give My Kids