This post focuses on the difference between push and pull in Lean. The goal of Lean is for every process to “flow value at the pull of the customer.” The key terms in this statement are defined below:

- The ultimate Customer is the end-user – who the product or service is providing value for. The other customer is the next step in the process. What does the next step need, and when do they need it?

- Flow refers to how value is created in a process. In a “perfect process,” value is created during every step, without any waste (or delay) in the process.

- Value is defined by the customer (end-user or next step). Every step should create value in the eyes of the customer.

- Pull refers to letting the customer have the product or service when they want it. The opposite of pull is push, and understanding both terms will help every leader make better operational strategic decisions for their business.

Push Production

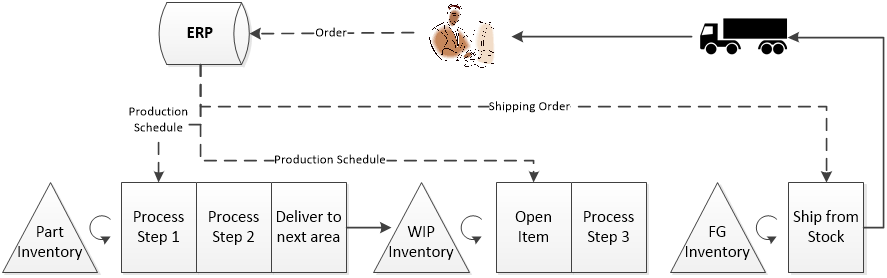

We will first define the traditional method of scheduling a manufacturing or service process, what we call “push” production. Push production is “Make to Stock” and is based on a demand forecast. Below is a simple example of a “Make to Stock” value stream map.

Push methods are very common in any Mass Production or factory setting that uses Enterprise or Material Resource Planning (ERP/MRP) systems to manage the business. They are also common in most service-based businesses that book customer appointments around the company schedule. Another example of push includes a dinner buffet at a restaurant (where much of the food is not eaten and is thrown away). Or any plane, train, or bus schedule where the company sets the schedule and then hopes people buy enough tickets to profit.

Push production can often be identified by the key performance indicators (KPIs) used by an organization. Here are a few push KPIs, and their goal for push production:

- Production output (higher or more is better, regardless of demand)

- Machine utilization (high utilization is better)

- Employee utilization (being busy is better)

Pull Methods

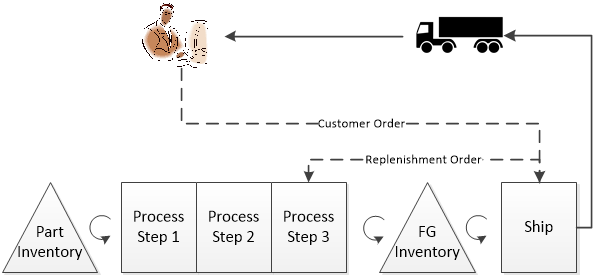

Methods of “pull” production are based on the concept that customers should have the product or service delivered when they want it. Pull methods are, therefore, more flexible and designed to “Build to Order.” Giving the customer control over the schedule leads to reduced waiting (and waste) in the eyes of the customer. It also increases demand variation and forces an organization to design flexible and adaptable processes.

Examples of pull production include:

- Ordering a computer with exactly the components and internals the customer desires and is built to order for the customer.

- Brewing a cup of coffee in a Keurig machine allows a customer to select the roast and flavor they desire without waste.

- A walk-in clinic that operates without appointments so customers can visit whenever they need the service.

- Online accounts that allow customers to check and update status when they want to, rather than sending updates. A good example of this is using a tracking number for a shipment.

- Toyota building cars on their assembly line one at a time, based on dealer orders for model and color, versus Henry Ford making thousands of identical black Model-Ts.

The metrics of success in a pull system are very different than a push system. A few pull production KPIs include:

- Customer lead time (shorter time to deliver the value is better)

- Throughput (the average output per unit time, higher is better)

- Cycle time (moving more quickly through a process is better)

- Inventory turns (a measure of inventory in the system, both work-in-progress [WIP] and finished goods)

Pull doesn’t focus on traditional metrics of output and utilization. An output that a customer hasn’t pulled is just overproduction and leads to the need to transport and store extras as inventory.

Pull is Preferred in a Lean Process

It is better for most organizations to use pull methods since the customer (not the company) determines when to pull value in Lean. Pull methods force processes to improve so they increase flexibility and reduce inventory. Changes to customer demand can be made more quickly. Customer relationships are typically stronger and “stickier.”

Push is based on “just in case” thinking. Pull is based on “just in time.” Large organizations will often combine pull methods with some level of push. For example, the computer company that builds to order based on customer pull will often still stock a few popular configurations. In addition, individual components inside the computers might be ordered by demand forecast and stocked as inventory.

Moving from push to pull is never easy. The Lean East team helps organizations continually improve their processes to focus on increased customer value. For example, combining push and pull using Kanban methods works well as an improvement step in many processes. Designing a process so customers can pull what they need when they need it, is always the goal.

Pull Innovation

Lean Startup Thinking focuses on using simple experiments to learn how customers respond to your product or service. The best experiments allow customers to test innovative ideas and provide feedback. One simple test is offering the product or service to consumers to see if they will pull it, or choose to buy it. Other tests are run by offering the product before it is even available. This is the model Kickstarter campaigns use; a campaign is only successful (and needs to be fulfilled) if a critical mass of people pull the service.

The Prosperity Paradox by Clayton Christensen explains why pull strategies are also superior to push methods when it comes to helping low-income countries develop. Every year, billions of dollars in aid are pushed through development programs to help countries grow their economies. These efforts nearly always fail. A better way to grow economies is for innovation that allows the people to pull in. That way, they would pay for what they truly value. A few economies where pull innovation strategies have succeeded include America in the nineteenth century, Japan after World War II, and South Korea today.

The Prosperity Paradox by Clayton Christensen explains why pull strategies are also superior to push methods when it comes to helping low-income countries develop. Every year, billions of dollars in aid are pushed through development programs to help countries grow their economies. These efforts nearly always fail. A better way to grow economies is for innovation that allows the people to pull in. That way, they would pay for what they truly value. A few economies where pull innovation strategies have succeeded include America in the nineteenth century, Japan after World War II, and South Korea today.

Marketing teams also differentiate between push and pull methods. Pull marketing tactics use advertising, promotions, and referrals to engage a consumer and build brand awareness. The hope is a few of the people seeing the commercial and learning about the benefits will choose to become customers. Pull marketing assumes customers will use a product or service on their terms – when they need it.

Flow Value at the Pull of the Customer

Your overall goal should be processes that flow value at the pull of the customer. Always respond to real demand rather than an imperfect forecast.

Understanding the importance of pull is hard for many leaders who have used push methods their entire careers. Please leave your questions about the importance of pull below. If you have additional examples about push versus pull methods we would love you to share those as well.

Excellent explanation and crucial for understanding Lean concept in general.

I come from Serbia which has emerging needs for high-quality Lean services due to big automotive companies opening their production and where I try to establish a such-like consulting company.

However, large financially powerful consulting companies (which primarily provide financial trainings) see this as one time opportunity to take money and often engage people with no shop floor experience to talk about Lean.

This is why I like this article – only straight forward, concise and approach filled with facts and experience make certain companies decide to work rather with me and my team.

Wish you all the best in your work.

Nemanja Dzordeski

Thank you for your thoughts, Nemanja. It is a shame when large consulting companies try to “push” Lean thinking onto the employees. We prefer to expose the employees in an organization to the methods and have them “pull” us into projects where we can coach and support them!

Such a wonderful blog about push and pull and I appreciate your effort for bringing this in to notice. Great blog indeed, will visit again future to read more!! Thank you for this article! This is really very informative for us.If you are looking same kind of valuable information, then can also visit Wooltec.co.nz