How to Use Kotter’s 8-Step Process for Leading Change

Learn how to use Kotter’s 8-step process for leading change from his 1996 international bestseller Leading Change

Learn how to use Kotter’s 8-step process for leading change from his 1996 international bestseller Leading Change

Benefit from the compound effect in life and work by focusing on small, regular habits done consistently that compound over time.

The Lean East team shares a TedTalk by Atul Gawande on how to become great and the benefits of hiring a coach.

Lean East summarizes “How to Change: The Science of Getting from Where You Are to Where You Want to Be” the 2021 book by Katy Milkman.

Sign-up for improvement tips delivered straight to your inbox at personalkaizen.co and join the new Personal Kaizen community on your preferred platform.

Lean East Founder Steve Musica shares his 10 Rules for Life for the first time in the hope that these rules will help all of you improve and maximize your life.

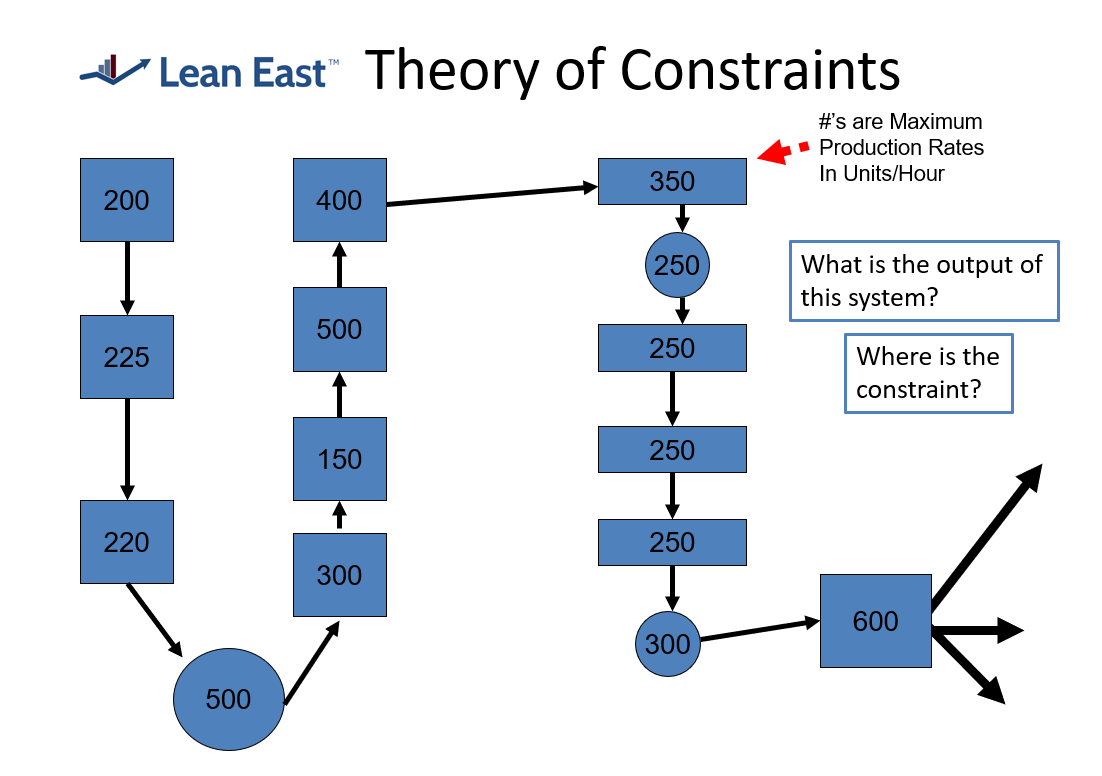

“The Goal: A Process of Ongoing Improvement” by Eli Goldratt. Learn how to use the Theory of Constraints to identify and eliminate process bottlenecks.

Learn the Lean East approach to developing new habits for Personal Kaizen. Major improvement will be realized by practicing the right habits for a few minutes every day.

Lean East clients experience increased profit and improved outcomes. Our business case for Lean thinking and Lean engagements includes five client examples.

Our Checklist Manifesto book summary. Learn about a simple and effective tool for getting tasks completed, getting them right – and saving lives!

Our website uses cookies to improve and personalize your experience. Our website may also include cookies from third parties like Google Analytics. By using the website, you consent to the use of cookies. Please check our Privacy Policy at the bottom of the page.