Is Your Organization High-Performing? Take Our FREE Performance Assessment

Learn about the Lean East PERFORMANCE™ Process and take our FREE Assessment to find out if Is your organization is high-performing.

Learn about the Lean East PERFORMANCE™ Process and take our FREE Assessment to find out if Is your organization is high-performing.

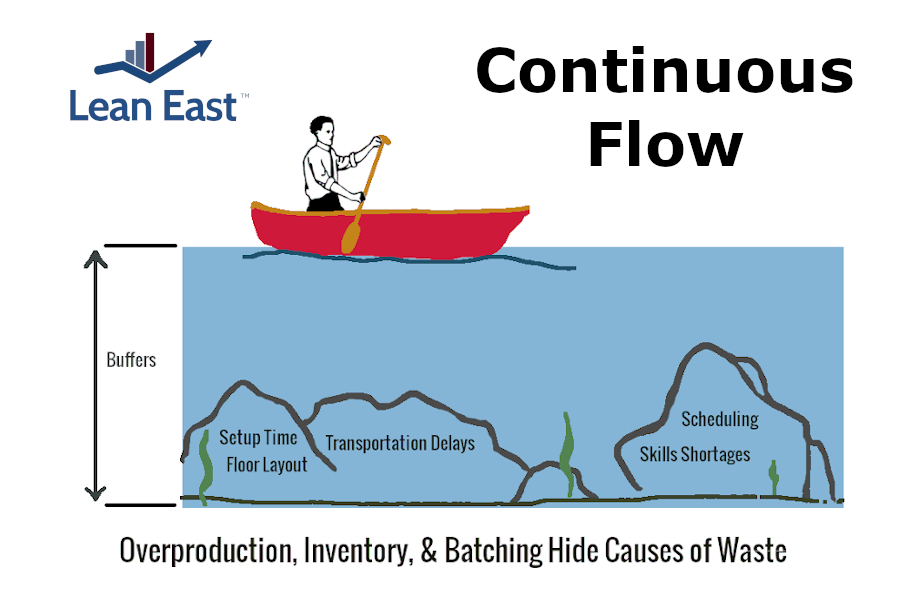

Lean East shares the benefits of trying to achieve continuous process flow – completing one piece at a time rather than batching. Reduce buffers to see problems!

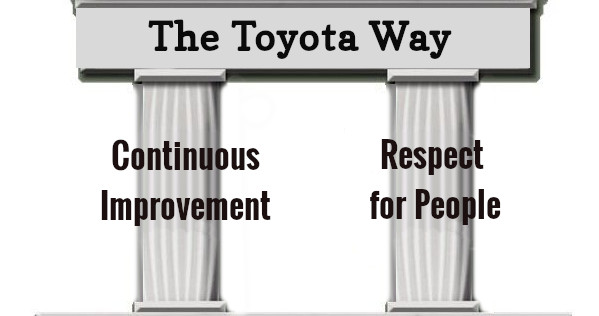

A summary of The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. How many of these principles are you following?

Our website uses cookies to improve and personalize your experience. Our website may also include cookies from third parties like Google Analytics. By using the website, you consent to the use of cookies. Please check our Privacy Policy at the bottom of the page.