Poka-yoke (pronounced poke-ah-yoke-aye) is the Japanese term for mistake proofing and the topic of our monthly blog post. Mistake proofing techniques are something every leader, engineer, and employee should be familiar with. There are many benefits to poka-yoke that we will share along with the levels of mistake proofing and examples. Taking a few minutes to consider mistake proofing techniques during the design or redesign of a process can save you significant time and money in the execution of the process.

Benefits of Poka-Yoke Mistake Proofing

Poka-yoke mistake proofing solutions seek to prevent errors from happening in a process, or at least allow them to be detected and contained at the source. Advantages of mistake proofing include:

- A reduction in quality errors or defects created by the process that is passed on in the process or to customers. This can save both time and money!

- Less time is spent on training workers since certain problems are prevented or obvious.

- Elimination of many inspection and quality control operations. There is no reason to double-check it was done correctly when it is impossible to make the error!

- Simplifying the process for the worker, since there is less to worry about if certain mistakes are prevented.

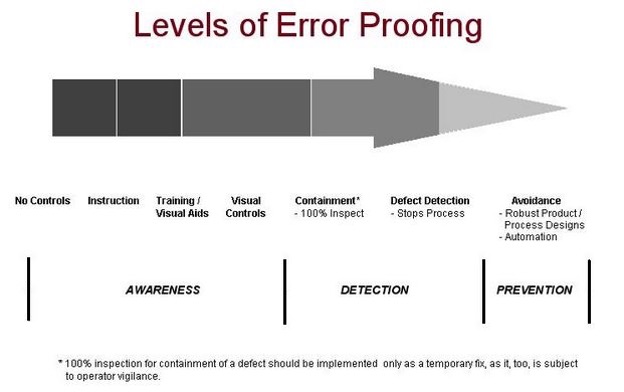

There are multiple levels of mistake proofing, including visual signals that help a worker, making the problem obvious and detectable, and (the highest goal) making a mistake in the process impossible to make. Learn more about these levels and the origins of poka-yoke below.

Fool Proofing

Japanese trainer and consultant Shigeo Shingo is credited with designing and popularizing aspects of the Toyota Production System, including popularizing the term mistake-proofing (poka-yoke).

Shingo was working with managers at Panasonic who described his work as “fool-proofing” (baka-yoke) processes. He berated the managers for using a term that is disrespectful to workers and substituted the word “fool” for “mistake,” since making mistakes is human. Shingo noted, “Mistakes are inevitable, but the defects that arise from them are not.”

Lean thinking requires respect for people, and suggesting your workers are fools isn’t respectful.

The First Poka-Yoke Device

We often share the story of the first reported poka-yoke device in our Lean Six Sigma Green Belt training program. Shingo was improving a process in which factory workers assembled a small switch. The workers would often forget to insert the required spring under one of the switch buttons, causing a defect.

In the redesigned process, workers first prepare the two required springs and place them in a small tray. They then inserted the springs from the tray into the switch. If a spring ever remained in the tray, the workers knew that they had forgotten to insert it and could correct the mistake.

Poka-Yoke Levels

The first poka-yoke device described above provides quality at the source and helps prevent a mistake from being passed on to the next stage of production. The example above is a lower-level method of mistake proofing as it provides a way to detect the problem at the source but does not prevent the mistake from happening in the first place.

The graphic below shares common levels of mistake proofing.

The best poka-yoke processes are designed to prevent errors rather than just make them visible. Look at the example in this video below to see one simple way of sorting by size.

Poka-Yoke Examples

Mistake proofing is often easiest and more robust when it is considered during the design stage of a product or process. Here are a few examples of good and bad mistake proofing designs.

Type of Poka-yoke: Awareness

The two terminals on the back of this monitor are side-by-side and the same except for the blue color. This makes it possible (and fairly easy) to plug your cable into the wrong terminal. Note that you are prevented from plugging into the S-Video port as that is a different terminal.

Type of Poka-yoke: Detection and Prevention

On the left is a USB 2.0 terminal. This can only be plugged in one way, but people will waste time detecting which way the plug fits.

On the right is a USB C terminal. This requires a different mating port but is able to be plugged in either way. You can’t make a mistake!

Customers will always prefer the terminal that works in either orientation!

Type of Poka-yoke: Prevention

This rectangular circuit board was designed to be installed using only three screws instead of 4. The missing screw means this board can only be installed in one way! A fourth screw in a rectangular pattern would allow the board to be installed in 2 ways (one correct and one wrong). This simple design decision makes it impossible for the worker to install it in the wrong orientation, thus mistake proof!

Summary

We hope this post encourages you to spend more time looking at how you can design your process to prevent mistakes or at least make them able to be detected before they are passed on. Please add any questions in the comments and we will be sure to reply.

Related Posts

Is Your Organization High-Performing? Take Our FREE Performance Assessment

The God Complex: Why We’re All Making This One Mistake

How I am Changing the Career Advice I Give My Kids