At some point in every Lean improvement project, the team hits a “this is never going to work” wall. It might be after two days of listening to the office grouch doing her thing and you are D-O-N-E, or after the 7th virtual 2-hour meeting, or after the conference room has turned into a tangled mess of colored stickies and pens, and the mapping has escaped the walls and started covering up most of the windows. For the facilitator, it’s probably when the conversation circles around to the same thing for the fourth time and all their well-honed facilitation skills look awfully threadbare.

Lean improvement projects are as varied as the people and organizations who do them, which can be a bit surprising given how fond the industry is of something called “standard work.” But every Lean project emphasizes an in-depth understanding of the problems with how the work is currently getting done. The idea is that until you really truly understand what is going wrong, your solution is just as likely to make it worse, or cause a new problem, than it is to make it better. This is counterintuitive for a lot of people whose professional experience has taught them to “bring solutions, not problems.”

The Messy Middle

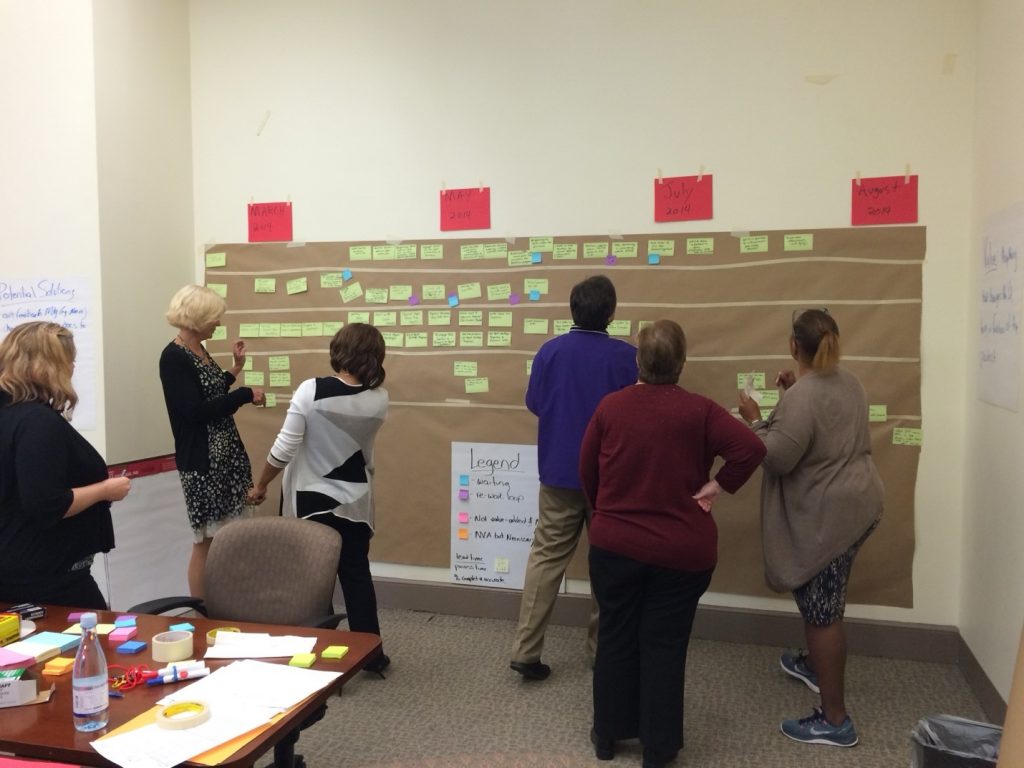

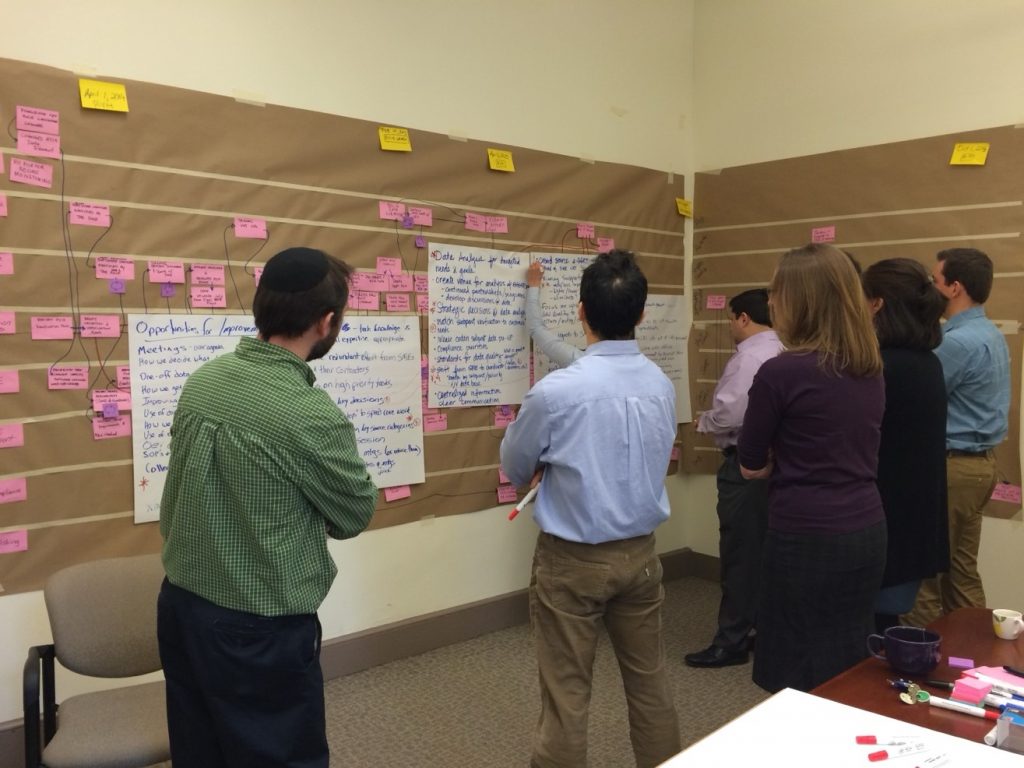

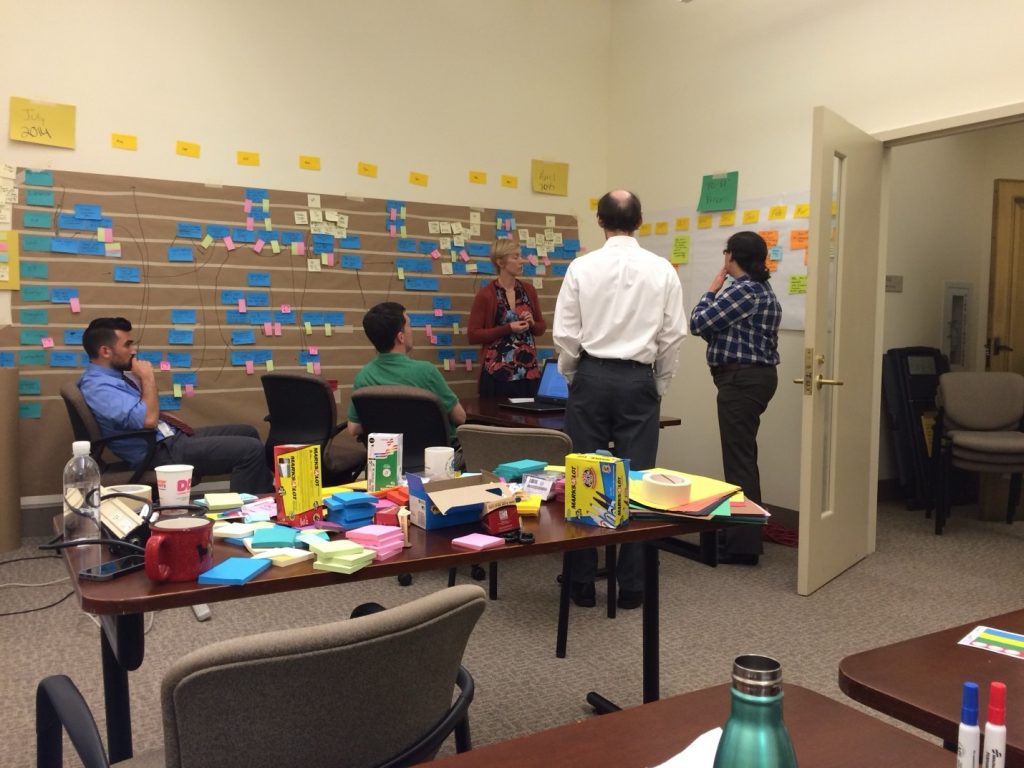

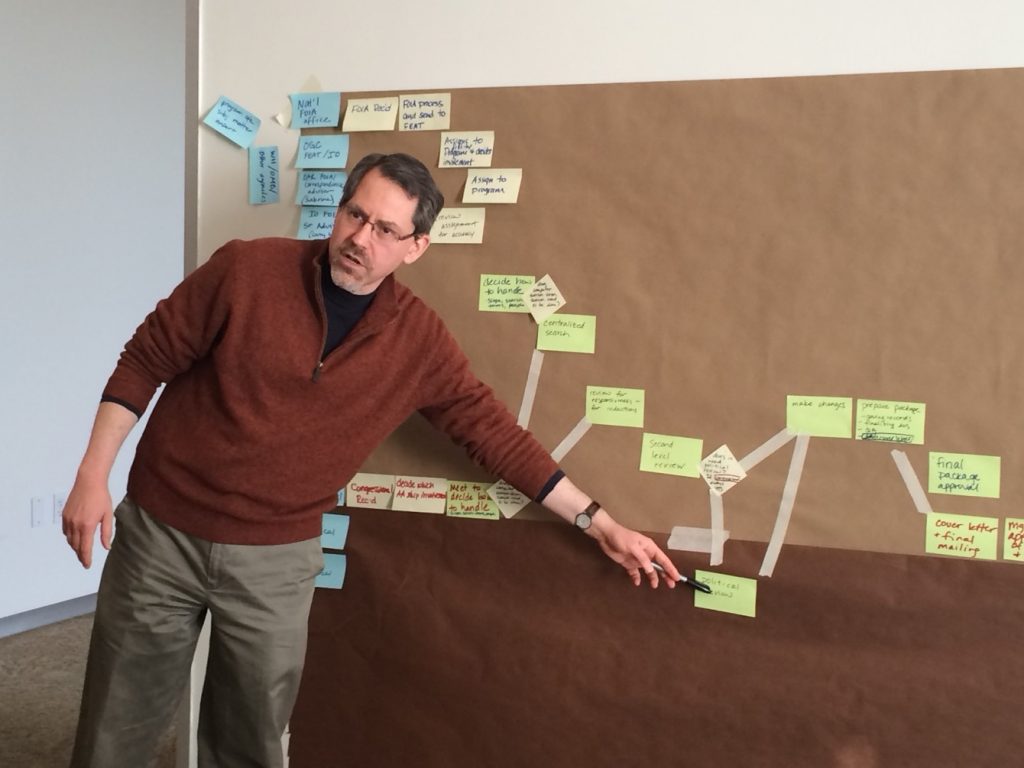

This is why Lean project rooms eventually start to take on the vibe of a 5-alarm fire. They get covered with paper squares, rectangles, triangles, stars, lightning bolts, arrows that lead nowhere, and arrows that circle back around on top of themselves in most colors of the rainbow. You have to write up a legend on the side to keep them all straight. The team talks for hours (…are we allowed to make that change? We added that step for a reason! Yes, in 1997. Things have changed a bit since then in case…). Yes, count up the number of approvals (…are you kidding me? There are 17 review steps?? That can’t be right. Count again!)

They talk about how long it takes to do each step, and what proportion of that time is waiting for someone to find the 10 minutes to get it done (answer: usually almost all of it). They even estimate what proportion of the work is really what the customer or client needs and how much is for regulatory documentation or the lawyers (…only 25% for the client? No! I knew it was bad, but it’s not that bad! Is it??…) Regardless of whether your project is in-person or virtual, compressed into a few days or spread out over months, sooner or later there comes a time when it feels like all this attention to problems is exactly the wrong way to go about finding a solution.

And yet. As everyone who’s been in a long-term relationship, raised a child, run a business, grown a garden, been in recovery, built something, grieved someone, spent long hours in the hope something good will come out of it, been active in a volunteer organization – in short, everyone who has spent time as an adult – knows, you have to go down into the darkness to come out the other side. In process improvement, there is no short-cut if you want to get it right. You have to face the problems head-on, take them out, and examine them closely – together as a group – before you can find real answers.

The Untangling

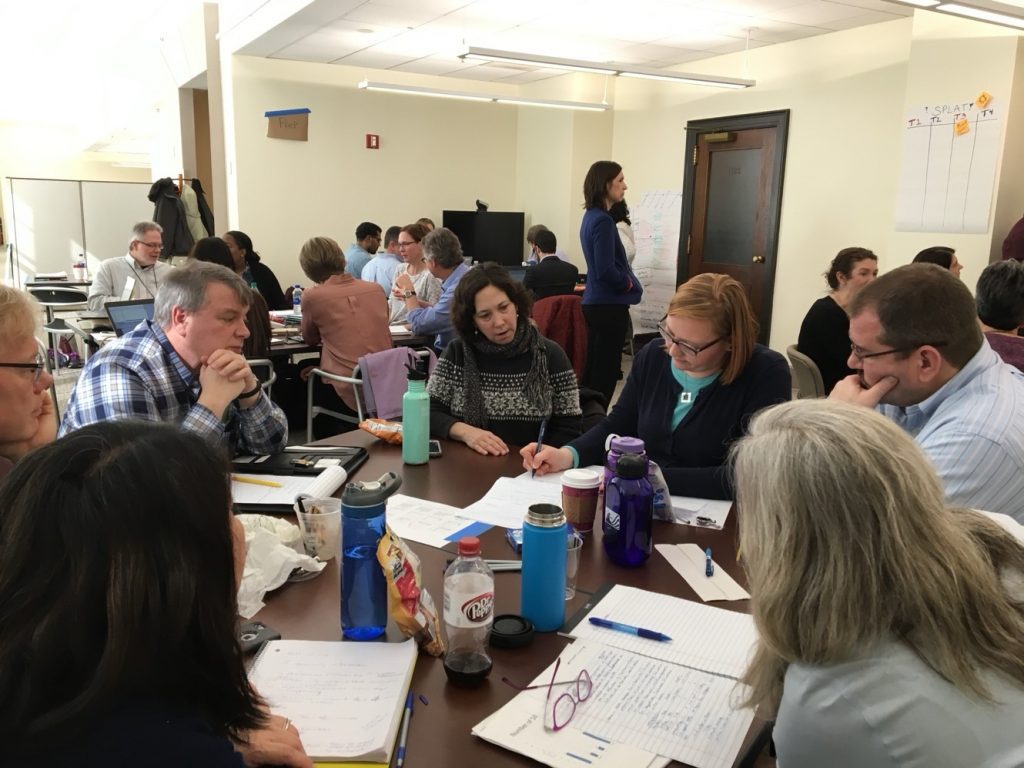

And the answers always come. I have been facilitating Lean projects for 12 years now, and I have never had a team fail to come out of the tunnel on the other side. What’s more, all that time spent on the problems turns out to also be time spent on solutions. The deep dive into problems helps people get clearer about what is really going wrong, and to test their ideas against what other people on the team think the problem is.

They learn to see how their roles fit into the work as a whole, and that in most cases the colleagues who seem to be making their lives harder are in fact doing the best they can in a broken system. (…oh! now I see why the request ends up on my desk with 12 hours to spare… All this time I thought she was incompetent. I had no idea no one ever told them how to do their job!…You mean you never look at that form at all??…It really wouldn’t help you if I sent the data earlier?…I had no idea my last minute edits were causing so much trouble…) They learn how to talk about problems and give feedback on solutions constructively, so the improvement conversation keeps going instead of getting stopped in its tracks at the first objection.

And so, when the time comes to build the new system, the team is ready. They’ve had the history conversations and the people conversations, and they understand how processes get gummed up. They might have a hole in the “to be” process where they want new technology or a new person, and until those are available, they’re going to have to make do with a workaround. There are always some tools still to build to make the “to be” process work, like a tracking board or that pesky standard work (which is just step-by-step documentation of the official and unofficial steps to get the work done). That’s OK. The team knows where they are going, they’re on the way, and they have an idea of the pitfalls to watch out for.

Moving Forward

The emotional ups and downs of making improvements don’t end with a great new “to-be” process, of course. There are roadblocks to implementation, and there will still be bad days. But just like in life, once you’ve made it through the first difficult stretch and come out the other side, you know it’s possible. Not only that, you have new skills and your team has new skills, and hey, if you get stuck, there’s always a Lean facilitator who can walk part of the way with you.

Please reach out to contact us or leave your comments and additional tips below.

This is a guest post written by Lean Six Sigma Black Belt Tamara Saltman. Tamara is a trained coastal ecologist, a licensed clinical social worker, and for the last 12 years, a Lean process improvement facilitator with the federal government. As she tells her Lean project teams, “basically, I just like looking under rocks.” Appropriately, she currently lives in Rockland, Maine and is ready to support improvement projects. You can find out more about her at tamarasaltman.com.

Related Posts

The God Complex: Why We’re All Making This One Mistake

How I am Changing the Career Advice I Give My Kids

How to Speak so that People Want to Listen