We recently came across an interview with Elon Musk on his SpaceX campus. The Everyday Astronaut asked Musk about his design and improvement process. In the short walking interview, Musk shares the biggest mistake most engineers make and his five-step improvement process. Check out his thoughts on process improvement and let us know what you think he gets right and what he is missing.

Elon Musk

Elon Musk is a visionary entrepreneur who wants to change the world and is currently my favorite example of a true engineer. If you don’t already know what he is involved with then here is a reminder:

- Founder and CEO of Tesla, the world’s leading electric car company, and focused on self-driving technology,

- Founder and CEO of SpaceX, a space exploration company developing reusable rockets to transport humans and cargo to Mars,

- Co-founder of Neuralink, developing brain-computer interfaces,

- Co-founder of OpenAI (developer of ChatGPT)

- Founder of The Boring Company, developing tunneling technologies to reduce traffic congestion,

- Owner of X (formerly Twitter) one of the largest social media platforms in the world

- President of the Musk Foundation (as the wealthiest person in the world, with an estimated net worth of US$232 billion as of September 2023, according to the Bloomberg Billionaires Index, and $253 billion according to Forbes).

Musk famously stays involved at the engineering and design level with many of his companies. As an expert in Lean Six Sigma methodologies, I have personally been impressed with Musk’s results while questioning his methods for achieving results (see below).

Elon Musk’s Five Step Improvement Process

This short video summarizes Musk’s five-step process:

1. Question the requirements

I love that Musk begins his process by examining the requirements. This is akin to our thoughts on “take time to understand the problem before you look for a solution.”

Musk is correct that too many of us (including engineers) are trained to narrow our focus on an issue rather than step back and examine the overall goal or purpose of an initiative or process. A good first step in improvement is to challenge the assumptions – ask questions that will help you understand the overall purpose, the problem being solved, etc. – before you work on improvement.

2. Remove unnecessary process steps

This is a great initial step in process improvement. We use Lean principles to help separate the value added steps from waste in a process. Musk is correct that “if you are not occasionally adding things back in, you are not deleting enough.”

One exercise we often use with our clients who are improving a process is to define and map the “ideal process.” The ideal process contains no excess (wasteful) steps but is also meant to be impossible or impractical to achieve. Focusing on the ideal step is akin to zero-based budgeting, where rather than subtracting waste in a process (or budget) you rebuild the process including only value right from the beginning.

3. Optimize

Musk doesn’t spend much time describing his “optimize” stage, but this is where you focus on putting the remaining process steps (or remaining necessary parts in the design) in the order or configuration that maximizes output while minimizing cost.

4. Accelerate time-to-learning

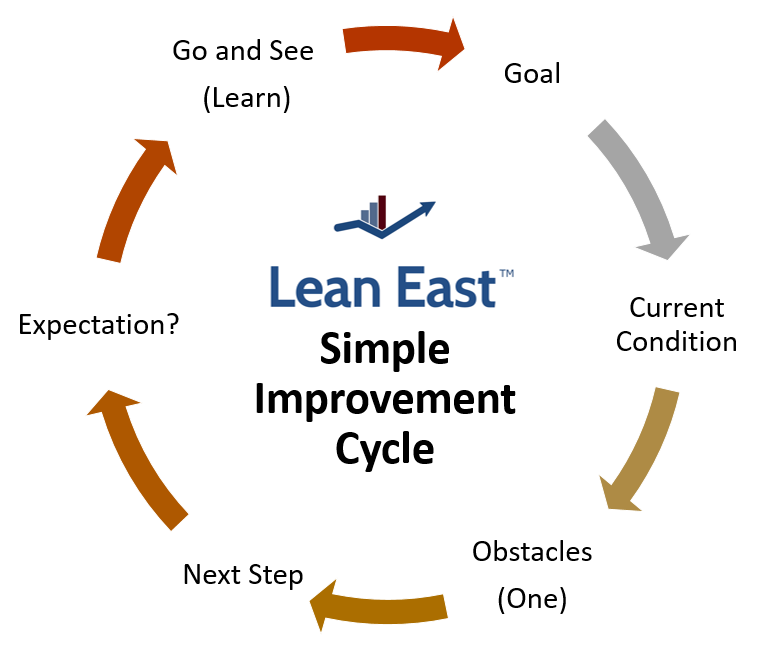

Process improvement is best when it is continuous. Musk is correct that the goal is to continue to experiment with improvements that might improve the process. The key to rapid improvement is rapid testing – rapid learning. Musk doesn’t provide much other detail here, but we have several continuous improvement posts if you want more info.

5. Automate

This is the final step in the process and an area where Musk admits to past mistakes. Automation should only be done after you have eliminated the waste in the process. This is one of the main reasons we encourage all clients to get Lean East help with improving their process before they install new software or use tools to automate steps. We have generated large ROIs for clients through improving before automating, and even eliminated so many unnecessary steps and requirements that automation was canceled!

What is Missing from Musk’s Improvement Process?

We hope you learn something from this video and summary of Musk’s five step improvement process. It is great that he acknowledges past mistakes from earlier in his career. We observed several issues ourselves when Musk was first setting up his Tesla manufacturing process without utilizing some key Lean principles.

“Everyone’s wrong. No matter who you are. Everyone’s wrong some of the time.”

– Elon Musk

Please let us know what you think about Musk’s five step improvement process. We have several additional thoughts to share with you but we would love to have a few comments from other Lean Six Sigma process improvement experts first.

Related Posts

Is Your Organization High-Performing? Take Our FREE Performance Assessment

The God Complex: Why We’re All Making This One Mistake

How I am Changing the Career Advice I Give My Kids