This month we are happy to share a simple yet powerful tool that will benefit any organization. It is the Lean Kata approach for developing a culture of scientific thinking at all levels of any organization.

What does the word “kata” mean?

Kata is the Japanese word for “form” and refers to a detailed, choreographed pattern of movements practiced alone or in groups. Anyone who has ever practiced the martial arts has performed katas in front of a sensei to advance and earn additional belts. The kata allows the trainee to memorize and perfect the movements being executed. That way, they can then easily make the movements later using muscle memory.

The Lean Kata was developed by Toyota and has been well described in the Mike Rother book, Toyota Kata: Managing People for Improvement, Adaptiveness, and Superior Results. Professor Rother has also made excellent resources available to help with the Toyota Kata principles at this site.

Toyota has long sought to develop managers and employees so that they have a competitive advantage. They do this by having their organization’s leaders and managers practice a deliberate routine or kata. This kata develops desired leadership behaviors. Toyota believes great leadership can be developed through good habits. Great habits then lead to great behaviors and also great culture.

The Lean kata consists of two parts: the improvement kata, and the coaching kata.

The Lean Improvement Kata

The improvement kata is a routine for moving from the current situation to a new situation in a directed way. It is based on a four-part model:

- Understand the vision or challenge

- Grasp the current condition

- Define the next target condition (how you want to improve towards the goal)

- Move toward that target condition iteratively, uncovering obstacles that need to be worked on

The improvement kata focuses on experimentation and learning. Teams can use the steps together to easily communicate with each other. They can also communicate with supervisors who may be coaching them. With proper practice of the improvement kata (also supported by good coaching), the brain will then form the practice into a new habit.

The Lean Coaching Kata

Once an individual masters the practice of the improvement kata, then they move into a leadership role. The coaching kata is a routine that develops the habits of the improvement kata for employees on the team. Coaching will help employees develop the proper habits of the improvement kata faster. It will also help employees develop habits more completely. This will then promote forming new neural pathways.

The coaching kata helps leaders coach their people in a scientific way of thinking and acting. Lean thinking requires respect for people. One of the best ways to demonstrate respect is to help those closest to the action develop their own solutions to problems and increase customer value.

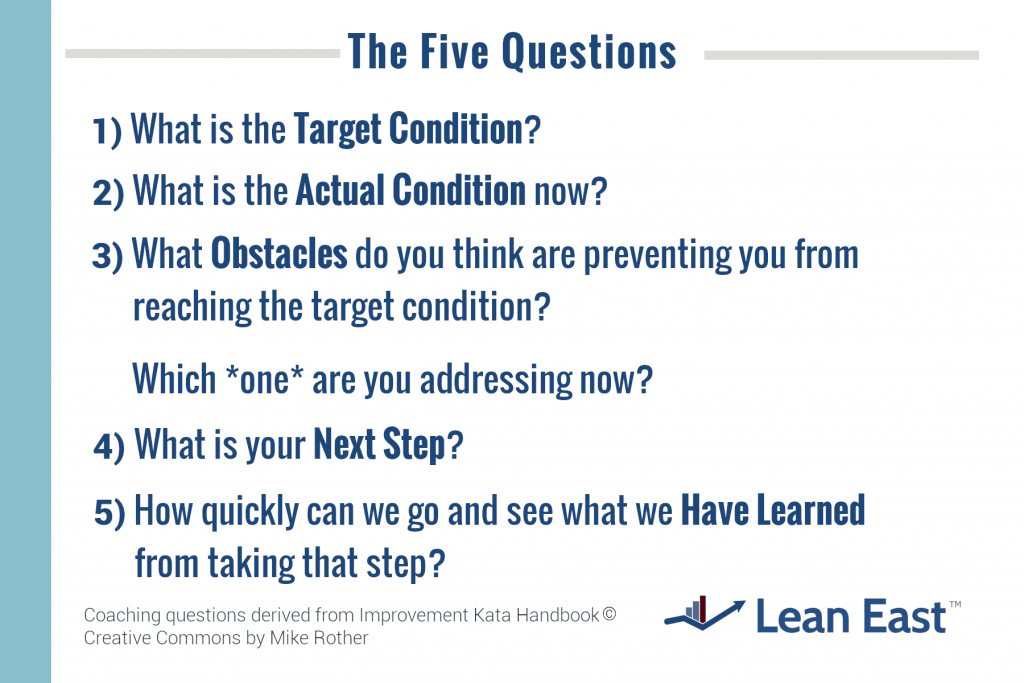

The coaching kata requires leaders to ask the following five questions to the individuals and teams they are coaching. The questions should be asked when the need arises but at least once daily, typically at a daily huddle.

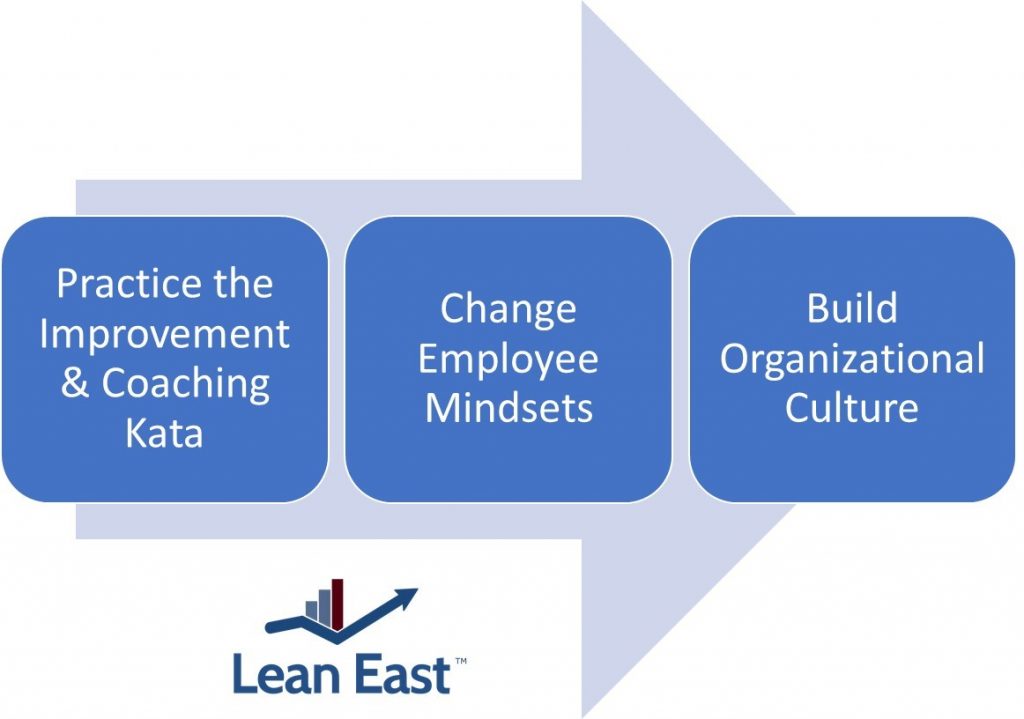

Regularly practicing the improvement kata develops problem-solving skills. Likewise, regularly practicing the coaching kata develops leadership skills. In conclusion, regular use of both leads to many experiments that allow the organization to learn. This includes what customers value and also how to better deliver that value and avoid waste.

Benefits of the Lean Kata to Develop Scientific Thinking

Once a kata is fully learned, people on the team can derive confidence from the kata for working through any uncertain situation. Major benefits from practicing the improvement and coaching katas include:

- Communication about the organizational vision and goals

- Rich discussion from teams about the vision and challenges

- Respect for people at all levels of the organization

- Creative problem solving

- Employee confidence

- Reduced risk-aversion (employees are encouraged to experiment and try out ideas)

- Job satisfaction

- An improved organizational culture

Members of the Lean East team include very experienced coaches who help organizations experiment and grow using the improvement kata and coaching kata. Please connect with our team if you want to learn how these methods have benefited many different organizations. These organizations include large and small, for-profit and non-profit, and more!

Related Posts

Is Your Organization High-Performing? Take Our FREE Performance Assessment

The God Complex: Why We’re All Making This One Mistake

How I am Changing the Career Advice I Give My Kids