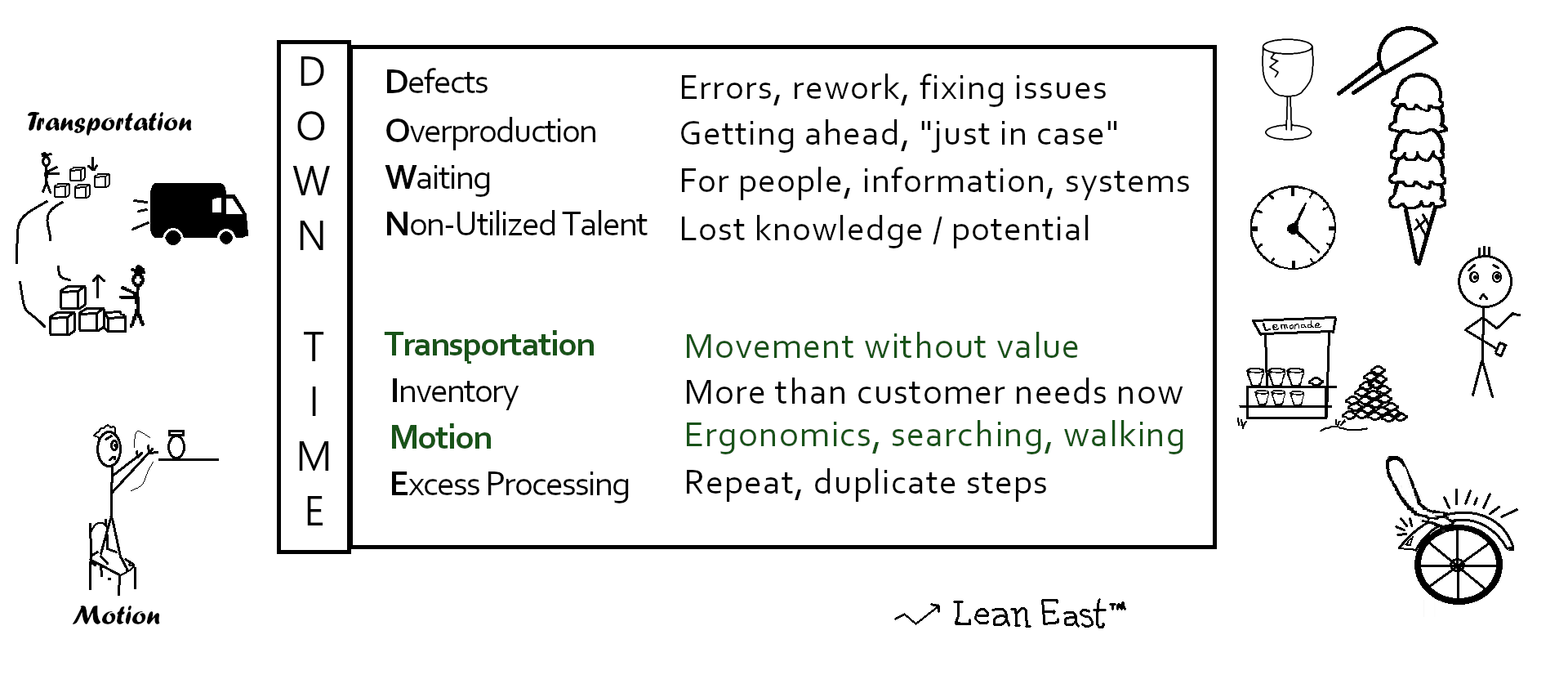

Learn about the 8 Lean wastes to minimize from your processes and how to differentiate between the wastes of Motion and Transportation.

We enjoy teaching the 8 Wastes of Lean Thinking to our clients and the participants in our training workshops.

As instructors, we share examples of wastes from our professional experience in both manufacturing and service-related organizations. Together, we brainstorm ways in which the wastes reveal themselves in our attendees’ organizations.

One question that gives us pause in every Introduction to Lean Thinking workshop is the request to explain the nuance of two ‘movement’ wastes – motion and transportation.

Motion

The motion waste focuses on the movement of people or equipment that is unnecessary. It is any movement beyond the minimum required for completing the process step.

The motion waste is typically found within a workspace or process step rather than between steps. Walking to a community printer or searching for information or a tool are both wastes of motion. Ergonomic issues – reaching, stacking, repositioning, and clicking – are also common.

Examples of ‘Motion’ Wastes:

- Clicking through multiple folders on the network drive to find the information you need

- Flipping over a fixture to orient it properly for use

- Searching through a toolbox to find the necessary tool for the job

- Arranging surgical tools on a tray or table so they are oriented properly

- Walking between office spaces to check if the mail has been delivered yet

- Thumbing through a manila folder to find the proper form to hand to the customer

- Copying information from one application to another file

- Searching for the information you need on a form

Wasted motions can be large or small. Large motion waste is often identified as walking or traveling between work areas or to a centralized storage room.

Several clients have noted that they like needing to move from their desk and stretch occasionally. We like stretching too, but it is still wasteful if your process requires wasted movement to complete the work. It is better to remove the waste, finish your work more efficiently, and have 15 minutes available for a short walk outside on a sunny day.

Small motion wastes may seem insignificant at first, but they really add up. For example, using an automatic screwdriver to eliminate twisting motion when tightening a screw may save just a few seconds per turn in a workstation, but many hours of time over the course of a week, month, and year. Implementing good “5S” visual workplace practices will generally eliminate many of your small motion wastes.

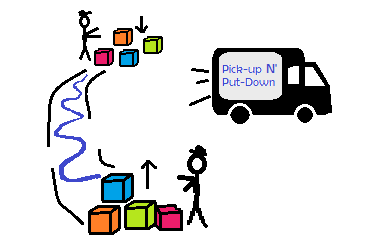

Transportation

The transportation waste is not about the person or equipment creating the value, it is rather about the movement of the product, information, or customer itself when this movement does not create value.

Transportation occurs between process steps and workstations rather than within them. Transportation, like motion, is a highly visible type of waste.

The transportation waste in manufacturing can be easy to observe and identify. It may be pallets of product moved with a forklift, or trucks carrying product between worksites. Returning unsold product from retailers back to the warehouse is waste. Conveyors are often installed in factories that automate the waste. Don’t be fooled; it is still waste. Unnecessary transportation often occurs because of poor facility layout and poor logistics.

Lean East works with many service organizations (healthcare, government, construction trades, etc.) where large quantities of product are not moved around in a warehouse. For these clients the transportation waste is not immediately intuitive or tangible to identify. But once understood, these kinds of wastes begin to be revealed. In healthcare, patients often directly experience the waste of transportation as they are moved from waiting room to waiting room, with zero value delivered.

Examples of ‘Transportation’ Wastes:

- Interoffice mail that carries paper forms between departments for signatures

- Families visiting multiple offices or buildings to enroll students in a new school

- Moving equipment between job sites when schedules change

- Using email to share important important data and files rather than hosting files in a central data repository

There is Always room for Waste Identification and Improvement

Even consulting professionals can find new ways to find and remove waste! I recently eliminated several wastes from one of my financial processes by downloading my financial institution’s app that allows me to use my mobile phone to photograph the check front and back from the comfort of my office. This simple depositing feature is saving our team the time needed to drive to the bank (transporting checks), filling out deposit slips, and waiting in line.

Labeling waste is not the goal. Focus on eliminating waste

Wasted movement – Motion and Transportation – occurs when people and equipment, products and information, moves around without creating value. Ultimately, giving a name to the kind of waste you have identified is not the objective.

The effort that will improve your work processes for your employees and clients is to identify efforts that add value and remove the waste, whichever kind of waste it is.

This is the challenge we undertake with our clients. Learn more here.

[…] Whereas the first two rules of circular manufacturing create a more logical process for operators, the third rule helps cut motion waste and transportation waste. […]

Great insights on the distinction between transportation and motion! I never realized how much of an impact these forms of waste have on efficiency. Your examples really helped clarify how to identify and eliminate them in our processes. Looking forward to implementing some of these strategies!

Great insights on the distinction between transportation and motion! It’s fascinating how understanding these two types of waste can lead to more efficient processes. I appreciate the practical examples you provided; they really helped clarify the concepts. Looking forward to applying these principles in my own work!

Great insights on the distinction between transportation and motion! It’s fascinating how understanding these two concepts can significantly enhance efficiency. The examples provided really clarified their impact on lean practices. Looking forward to implementing some of these strategies in my own workflow!

This post really clarifies the distinction between transportation and motion in lean practices. I especially appreciate the examples you provided, which make it easier to identify these wastes in real-world applications. It’s fascinating how reducing these wastes can significantly improve efficiency. Looking forward to more insights on lean methodologies!

Great insights on the differences between transportation and motion! It’s interesting to see how both can impact efficiency in a lean environment. I never realized how much waste can accumulate just from unnecessary movement. Thanks for breaking this down!

I found the comparison between transportation and motion in lean waste really insightful! It’s interesting how both contribute to inefficiencies, yet addressing them requires different strategies. I especially appreciated the examples you provided—those really helped illustrate how small changes can make a big difference. Looking forward to implementing some of these concepts in my own work!

Great insights on the distinction between transportation and motion! It’s interesting how both can impact efficiency in such different ways. I especially appreciated the examples you provided to illustrate each waste. Looking forward to implementing these principles in my own processes!

Great insights on the distinction between transportation and motion! It’s fascinating how understanding these lean wastes can significantly improve efficiency in workflows. I especially appreciated the examples you provided; they really highlighted the practical implications of reducing these wastes. Looking forward to applying these concepts in our operations!